Best Design For Mills and Corrugation Shops

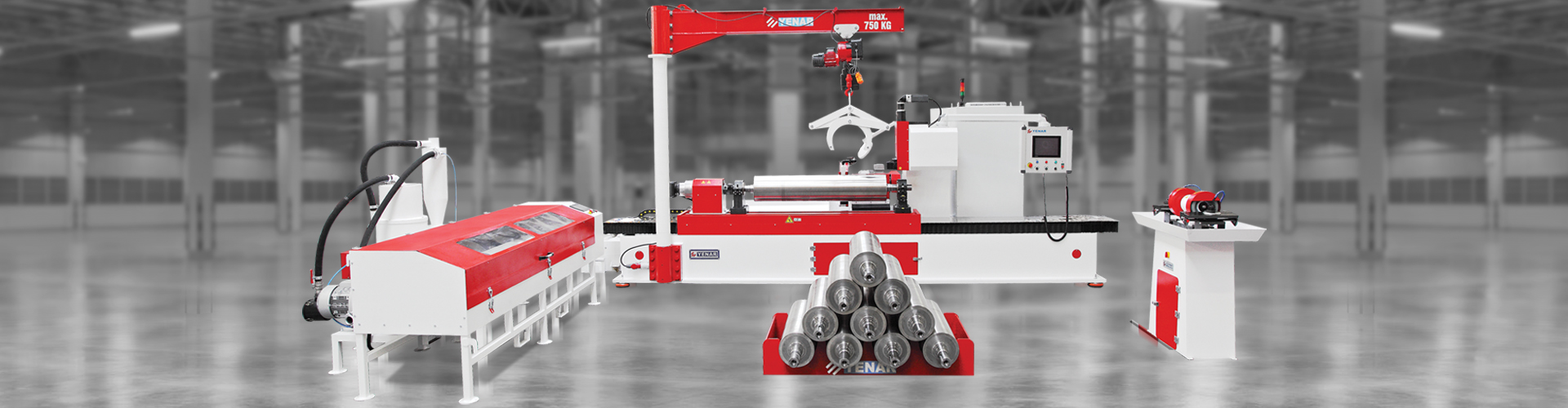

YENAR combined with its experiences and powers in roll manufacturing for 25 years and it has decided to produce its own machine as the existing machines in the market were not meeting the requested of our company. As the machine was built by a roll producer and had many more advantages and very user friendly got a very big success in the sector then we suddenly became a machine manufacturer. Yenar have 2 different types as YF ( single fluting machine) and YFG (Combined fluting and Grinding) in 3 different sizes. The YFG and YF models are mainly designed for millers and corrugating shops.

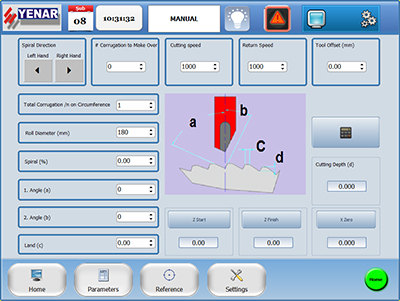

The software is designed by our IT engineers accordingly our experiences of the roll business. So it is very easy to operate it and user-friendly. The machines are the fastest one compare to other machines on the market and local languages can be added on the machine. On fluting operation, the most important thing is that the depth of the flute is automatically calculated by the machine according to flow sheet that you have to input into the screen. So you cannot make any mistake while fluting the rolls. Once the grinding cycle is designed as simple as possible to avoid any skills and it is also very simple as fluting cycle just the millers need to enter total cut and choose one of the pre defined grinding shapes (Cylindirical, Camber or Chamfer).

The software is designed by our IT engineers accordingly our experiences of the roll business. So it is very easy to operate it and user-friendly. The machines are the fastest one compare to other machines on the market and local languages can be added on the machine. On fluting operation, the most important thing is that the depth of the flute is automatically calculated by the machine according to flow sheet that you have to input into the screen. So you cannot make any mistake while fluting the rolls. Once the grinding cycle is designed as simple as possible to avoid any skills and it is also very simple as fluting cycle just the millers need to enter total cut and choose one of the pre defined grinding shapes (Cylindirical, Camber or Chamfer).

YF 35150 Fluting Machine

YFG 35150 Fluting and Grinding Machine

YFG 35150 Fluting and Grinding Machine

Roll Diameter

154 - 380 mm

(6" - 15")

154 - 380 mm

(6" - 15")

Roll Length

1.500 mm

(60")

1.500 mm

(60")

The YF 35150 model is mainly designed for corrugating shops that make seperately grinding and fluting operation. Users can only re-flute their own rolls with this machine. Concerning to model of YFG 35150 machine is mainly designed for millers they can firstly grind (chamfer, Cylindrical and camber) and re-flute their own rolls in the mills.

YF 45210 Fluting Machine

YFG 45210 Fluting and Griding Machine

YFG 45210 Fluting and Griding Machine

Roll Diameter

275 - 480 mm

(10" - 19")

275 - 480 mm

(10" - 19")

Roll Length

2.100 mm

(83")

2.100 mm

(83")

The YF / YFG 45210 models are generally designed for crushing rolls that have size such as 400x2100 mm rolls. These rolls are much more longer than the flour milling rolls so it is very difficult to flute these type rolls but YENAR gives guarantee that you can re-flute and grind these types of rolls in a very short time and high accuracy.

YF 60210 Fluting Machine

YFG 60210 Fluting and Grinding Machine

YFG 60210 Fluting and Grinding Machine

Roll Diameter

444 - 670 mm

(17" - 26")

444 - 670 mm

(17" - 26")

Roll Length

2.100 mm

(83")

2.100 mm

(83")

YENAR also is offering the biggest sizes YF / YFG 60210 Fluting and Grinding machine that is able to flute and grind for flaking rolls that is around the 600 mm on diameter rolls. With this model users can flute up to 670 mm on diameter and 2100 mm on length.

Grinding Shapes

Cylindirical Shape

If you want to take of the old corrugations or you want your roll to be fluted, you should choose 'Cylindrical Grinding'.

Chamfer Shape

This type of grinding using for smooth rolls and grinding head moves accordingly your parameters as shown..

Camber Grinding

This type grinding also using for smooth rolls and only parameter requested is the difference of diameter on the center and at the end of the roll.

User Friendly 12" Touch Screen

A special Windows based software developed by YENAR is running in the machine so if any problem with the control panel users have always the option to run the machine from any laptop or desktop. No need to wait a spare control panel.

Only need to input your flow sheet (Angles, Flutes/Circ, Spiral and Land) then start to flute.

Choose one of the grinding types for rolls and start to grind.

Only need to input your flow sheet (Angles, Flutes/Circ, Spiral and Land) then start to flute.

Choose one of the grinding types for rolls and start to grind.

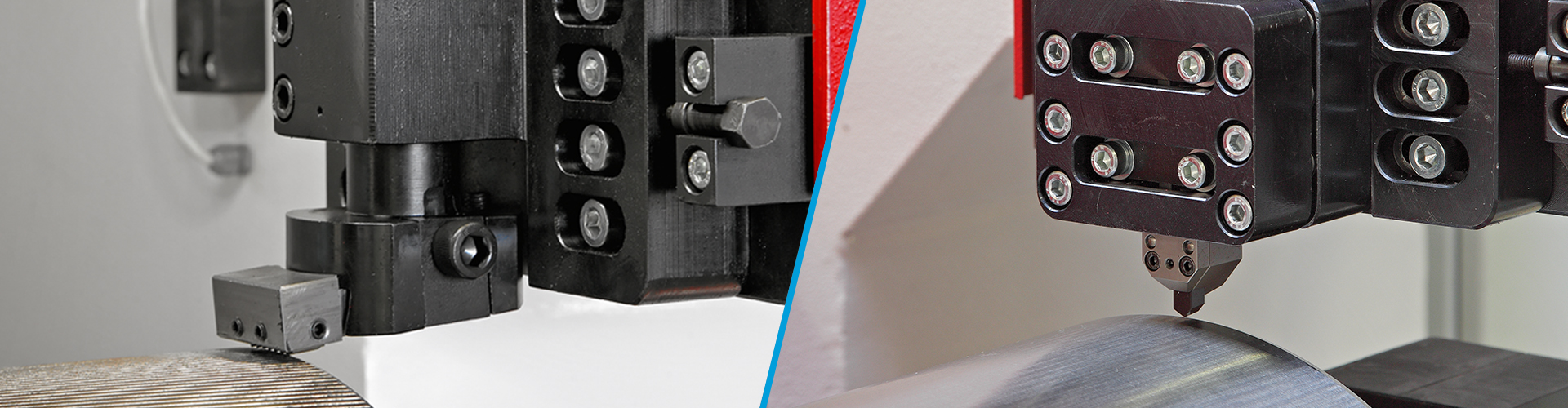

Tool Options

Single and Multi-point Carbide Options are available. It is possible to add local language if the users translate it.

Language Options

Turkish

Russian

French

Hindu

Arabic

Indonesian

Mongolian

Italian

Japanese

Spanish

YGB Yenar Carbide Grinding Bench

Yenar sharpening machine is designed to sharp your carbides accordingly your flow sheets. With the water cooled sharpening system that allows you to sharpen pratically any type of carbides. Users can sharp from 0° to 180°. YGB is mainly designed for the professional fluting work shops and is ideal when they exact angles need to sharp it.

Service, Spare Parts and Training

By connecting the machine to the internet and through the remote technical support, troubleshooting and error diagnosis. We offer 7/24 remote service possibility to our customers a powerful organization with highly experienced people that can identify and correct possible breakdowns and remotely.

We have a wide stock of original spare parts ready to be sent to client immediately. Our technical service provides support to find the right part and proceeds to send the items in the shortest possible time.

The training we offer is specially geared towards operators to ensure efficient and correct use of the machine. Together with the operators we perform practical training on topics related to mechanics, operating, trouble shooting, specific functions of the machine, compensation of drives, alarm messages, machine recovery instructions, instructions for preventive maintenance, etc.

We have a wide stock of original spare parts ready to be sent to client immediately. Our technical service provides support to find the right part and proceeds to send the items in the shortest possible time.

The training we offer is specially geared towards operators to ensure efficient and correct use of the machine. Together with the operators we perform practical training on topics related to mechanics, operating, trouble shooting, specific functions of the machine, compensation of drives, alarm messages, machine recovery instructions, instructions for preventive maintenance, etc.

© 2020 YENAR