Overview

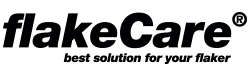

The FlakeCare from YENAR is a CNC mobile roll turning unit designed to refurbish flaking roll surfaces on-site without removing them from your flaking mill. Robust and easy to install, it ensures that your flaking rolls remain in perfect condition, extending their service life and improving the efficiency of your flaking mill. Regular maintenance of flaker roll surfaces is a necessary preventive action to avoid premature wear and damage.

The FlakeCare machine turns/machines the surfaces of the rolls directly in the mill, allowing for faster operations compared to conventional methods. Simply fix the unit to your flaking mill and operate it according to the roll’s condition, minimizing downtime.

| Application Sizes |

|

Roll Diameter: 600–812 mm (24”–32”) Roll Body Length: Up to 2,200 mm |

| Application Fields |

| Compatible with any brand of flaker machines |

| Features & Advantages |

|

- User-Friendly Proprietary Software - Automatic Chamfer Mode for both roll ends - Local Languages Supported (customizable) - High Accuracy for industrial-scale maintenance - Reduces Refurbishing Time by 60–80% - Quick and Easy Tool Replacement - Lower Total Operating Cost - Increases Flaking Mill Efficiency and Extraction Rate - Low Operation and Maintenance Cost - Servo Motor Controlled - Minimal Consumption of Spare Parts - Easy Installation - Integrated Remote Assistance Control |

|

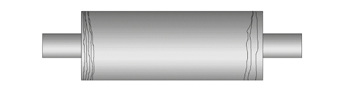

| Wire Effect |

|

Rolls may appear as shown in the photo due to the following reasons: -Excessive load in the center can cause a ‘wire effect,’ leading to breakage in the middle. -Misaligned feeder or poor knife cleaning. |

|

| Normal Wearing Rolls |

| This figure never happens in reality. |

|

| Polygon Effect |

| A polygon shape forms along the roll axis. These scatter marks are typical for rolls operating with differential speed. |

|

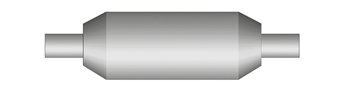

| Conical Wear |

| Incorrect feeding or uneven hydraulic pressure can cause conical wear on the rolls. |

|

| Breaking Ending |

| The surface and ends of flaker rolls wear regularly and may crack when rolls touch each other, causing material chips to split out. |

|

| Chamfer |

| Chamfering is available. |