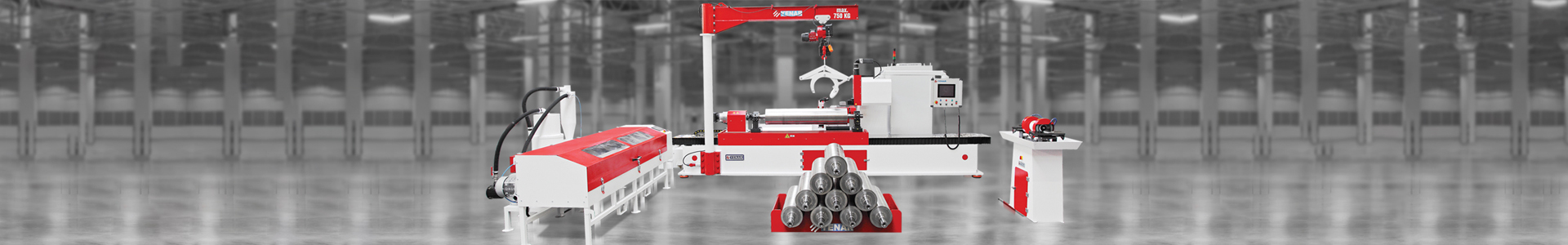

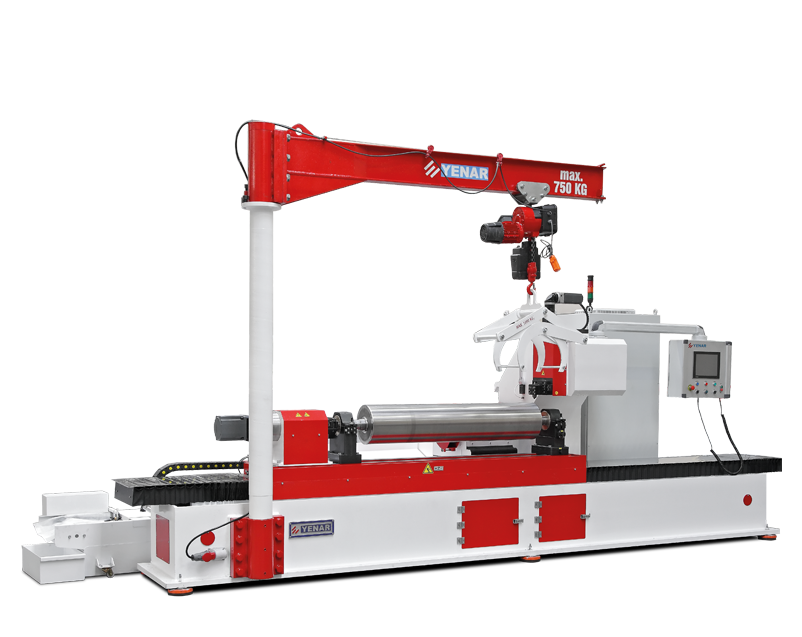

Overview

The YF 35150 is designed primarily for corrugating shops performing separate grinding and fluting operations, allowing users to re-flute their own rolls efficiently. The YFG 35150 is tailored for millers, enabling both grinding (Chamfer, Cylindrical, or Camber) and re-fluting of rolls directly in the mill.

* Crane is optional.

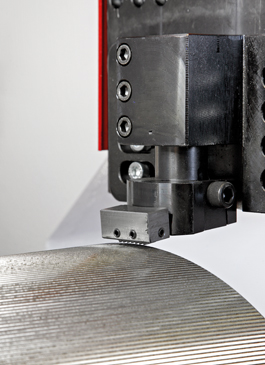

Working Principle

Fluting Operation: The machine automatically calculates the flute depth based on the flow sheet input via the touch panel, preventing errors.

Grinding Cycle: Designed to be simple and user-friendly; operators just enter the total cut and select a pre-defined grinding shape (Cylindrical, Camber, or Chamfer).

| Application Sizes |

|

Roll Diameter: 150–380 mm (6”–15”) Roll Body Length: Up to 1,500 mm (60”) |

| Application |

|

- Corrugating shops (YF 35150) - Flour, feed, and oil mills (YFG 35150) - Re-fluting and grinding of rolls in industrial operations |

| Features & Advantages |

|

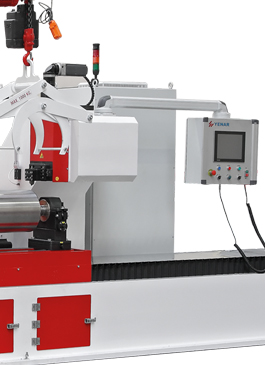

- 12” Touch Panel for intuitive operation - CNC Controlled for precision and consistency - User-Friendly Proprietary Software designed by YENAR - Local Languages Supported (more than 10 languages available) - Quick and easy replacement of tools and grinding stones - Options for single or multi-point tools - Ability to run the machine via laptop - Low operation and maintenance cost - Automatic lubrication system - Tool, table, stone, and index motors are servo motor controlled - Crane Option available for easy handling of rolls - Minimal consumption of spare parts - Easy installation for immediate use - Integrated Remote Assistance Control for troubleshooting - Helical Fluting Feature available for specialized applications |

|

| Cylindrical Grinding |

|

Used to remove old corrugations or prepare the roll for new fluting. Ensures a uniform cylindrical shape along the roll length. |

|

| Chamfer Grinding |

|

Designed for smooth rolls. The grinding head moves automatically according to the parameters you set, achieving precise chamfered edges. |

|

| Camber Grinding |

|

Also used for smooth rolls. The only parameter required is the diameter difference between the center and ends of the roll, allowing controlled camber shaping. |